Projects

Reverse engineering expertise ensures new parts can be made so that vital repairs can be carried out

NOT every toolmaker has the ability to repair, refurbish or reverse engineer tools they did not originally make.

Thankfully, our highly-skilled team do possess the knowledge and experience required to do exactly this.

And all of that expertise came to the fore when a long-term customer who produces components for the ‘white goods’ industry got in touch with something of an unusual request.

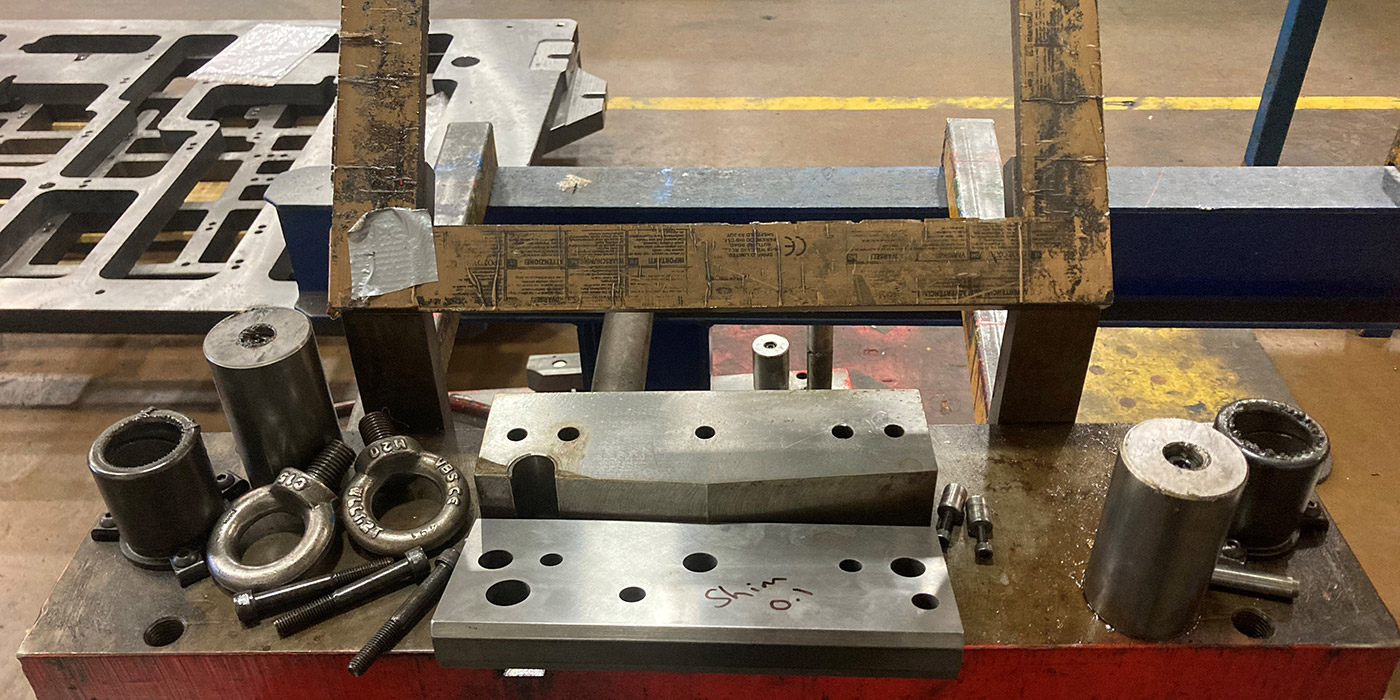

When the tool arrived, it was delivered with no information other than a note to say that a ‘New Punch and Die is required’.

Despite this lack of instruction, our expert toolmakers managed to reverse engineer all the existing parts required to conduct the repair – including:

- Reverse engineered the punch and die

- CAD design created for new punch and die

- Existing die sharpened to enable production until part manufactured

- A missing dowel was replaced with a new one

- Tool underwent final ‘alignment check’

Not only did this ensure the tool could be fixed, it also meant they could provide a quoting for new parts should they be required in future. In most cases, we can carry put a tool repair of this nature for a COST PLUS price, meaning the customer only pays for the time we spent working on the tool plus the price of delivery.

For anyone working in an industry which relies on the volume of components they produce, this service can be a lifeline.

Client

Manufacturer producing components for ‘white goods’ industry.

Overview

Reverse engineer new Punch & Die tool without any drawings.

Paragon Tools

321 National Avenue

Kingston upon Hull

HU5 4JB

United Kingdom

Contact

Company Registration Number: 16843484